Sand is a kind of frequently-used building material and essential fine aggregate in the concrete masonry. The sand quality and price have a great influence for the quality and cost of construction project, the influence is especially large for those who lack of sand areas. In the construction of railway engineering, no matter it is used as padding of water permeability, or directly used in the masonry of roadbed, bridge and culvert, tunnels, buildings and structures; the sand dosage are both large. If it all adopts long transport for sand using in engineering, it will directly affect the project price as a result of expensive transportation cost. So it is necessary to seek an alternative solution to solve the sand using problem.

In the mountain railway survey, it frequently meets the condition of lacking of natural sand but with resourceful stone material. In this case, it is considered to use hard rock blasting and rolling machinery, then making the certain grain size distribution mechanical sand instead of natural sand, applied in the concrete masonry.

The mechanical sand technical requirements applied in railway engineering construction

The mechanical sand is made by that limestone, dolomite, granite and basalt are blasted and rolled mechanically. The mechanical sand particle shape, stone powder content and grain size distribution affect the concrete workability, strength, dry shrinkage resistance, wear-resisting performance etc.

- Particle Shape-Because the mechanical sand is composed of gravel rolling, the surface is rough, grain shape is irregular and mostly is angular or flake particle. The different grain shape of mechanical sand have greatly influence for concrete workability. The flake particle mixing of concrete workability is poorer, the ideal grain shape is similar to the cube particles.

- Stone Powder Content-Stone powder is the fine powder less than 0.08mm. When mixing concrete, the mechanical sand containing the right amount of stone powder not only can improve the concrete strength, but also can improve the concrete workability. Generally the stone powder being controlled within 7% is more appropriate.

- Grain Size Distribution-If the mechanical sand grain size distribution is not good, the mixing concrete workability is also poor and easy to separate. So the mechanical sand particle more than 5mm should not be above 20%

The mechanical sand making machine applied in railway engineering construction

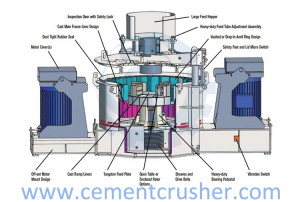

In the railway engineering construction, the sand making equipment includes VSI Series Sand Making Machine and 5X Series Sand Making Machine.

VSI Series sand making machine has the unique rotor structural design, wear-resistant materials technology, crushing speed optimization and hydraulic design, realizing the free transform between stone hit stone and stone hit iron. 5X Series sand making machine is researched and manufactured to improve the energy utilization efficiency, reduce the wear rate, prolong maintenance cycle, reduce maintenance time, increase crushing efficiency and control level. The sand making machine service life is improved above 48%, material throughput is increased by about 30%.

The economic significance of using mechanical sand in railway engineering construction

In the research of a railway, we considered primarily to adopt the mechanical sand instead of natural river sand in the roadbed, bridge and culvert, tunnels, buildings and structures. In the whole project design, the mechanical sand using is about 5 million cubic meter, it saves the investment of nearly 110 million dollars than using the natural river sand. This demonstrates that the application of mechanical sand has great economic benefits in the railway construction of lack of sand region.