Circular Vibrating Screen

Circular Vibrating Screens

Circular vibrating screen, also called circular-motion vibrating screens, are widely used to classify medium to coarse-grained bulk materials (1 mm to 400 mm) for screening.

Circular Vibrating Screen has high and strong screening forces produce efficient operation with circular motion being produced by one motor or exciter which feature low noise operation of 85 dBA.

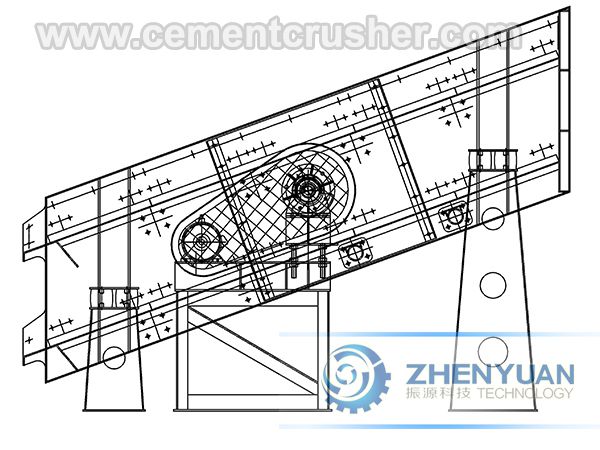

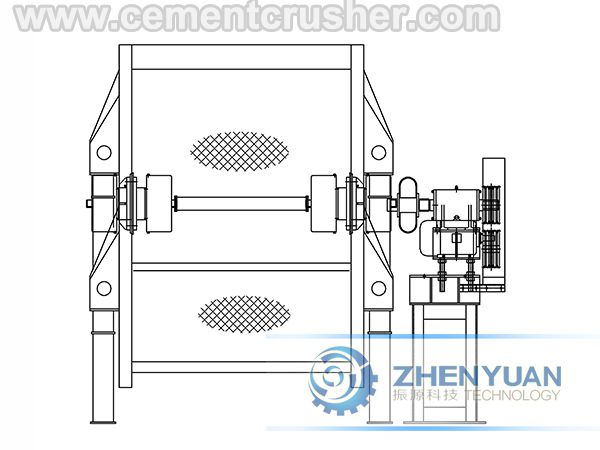

Working principle:

Circular vibrating screen operates using indirect excitation of the screen mesh. The entire screen frame is driven by unbalance unit which produce a circular vibrating motion.

Structure:

Areas of application:

- Screening of rock, ore, sand, stone, salt, coal and similar bulk materials, as well as in recycling and waste disposal.

- Screening of lumpy materials for quarries and the mining industry (sturdy design).

- Pre-screening of bulk materials (heavy-duty design).

Features:

- High capacity and efficiency can be achieved for either wet or dry screening, so suitable for outdoor working or the district with long rainy season.

- From fine to large separation sizes up to approx. 400 mm

- Connecting by ring-grooved rivets, hard deformation, stronger than welding.

- Low Impact: Low vibration transfer to surrounding structure

- High screen throughput up to 500 m3/ h, depending on size

- Dust enclosures, spray pipes.

- Screen surface inclination: 18°~20°

Screen Media

Your total screening solution

Zhenyuan supply a full range of screen media and consumables to complement the world-class screen machines that we manufacture. Whether your requirements be for polyurethane, wedgewire, wire mesh or rubber, we are able to supply it.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

| Model | Layers | Screening surface area (㎡) | Screening pore size (mm) | Feeding Grain Size (mm) | Capacity (t/h) | Vibration Time (r/min) | Double amplitude (mm) | Motor | Dimension L×W×H (mm) | |

| Model | Power (Kw) | |||||||||

| YA1536 | 1 | 5.4 | 6-50 | ≤200 | 100-200 | 730 | 8~11 | Y180L-8 | 11 | 3757×2975×2419 |

| 2YA1536 | 2 | 5.4 | 6-50 | ≤200 | 150-250 | 730 | 8~11 | Y200L-8 | 15 | 3757×2975×2419 |

| YA1542 | 1 | 6.5 | 6-50 | ≤200 | 110-220 | 730 | 8~11 | Y180L-8 | 11 | 3757×2975×2419 |

| 2YA1542 | 2 | 6.5 | 6-50 | ≤200 | 160-250 | 730 | 8~11 | Y200L-8 | 15 | 3757×2975×2419 |

| YA1836 | 1 | 6.5 | 6-50 | ≤200 | 150-250 | 730 | 8~11 | Y180L-8 | 11 | 3757×2975×2419 |

| 2YA1836 | 2 | 6.5 | 6-50 | ≤200 | 200-300 | 730 | 8~11 | Y200L-8 | 15 | 3757×2975×2419 |

| YAH1836 | 1 | 6.5 | 30-150 | ≤400 | 250-600 | 730 | 8~11 | Y180L-8 | 11 | 3757×2975×2437 |

| 2YAH1836 | 2 | 6.5 | 30-200 | ≤400 | 250-600 | 730 | 8~11 | Y200L-8 | 15 | 3757×3020×2437 |

| YA1842 | 1 | 7.3 | 6-50 | ≤200 | 220-400 | 730 | 8~11 | Y200L-8 | 15 | 4331×3020×2675 |

| 2YA1842 | 2 | 7.6 | 6-150 | ≤200 | 280-500 | 730 | 8~11 | Y200L-8 | 15 | 4331×3020×2675 |

| YAH1842 | 1 | 7.6 | 6-150 | ≤400 | 250-800 | 730 | 8~11 | Y200L-8 | 15 | 4331×3020×2700 |

| 2YAH1842 | 2 | 7.6 | 30-150 | ≤400 | 250-800 | 730 | 8~11 | Y200L-8 | 15 | 4331×3020×2700 |

| YA1848 | 1 | 8.6 | 30-150 | ≤200 | 150-525 | 730 | 8~11 | Y200L-8 | 15 | 4904×3023×2943 |

| 2YA1848 | 2 | 8.6 | 6-50 | ≤200 | 150-525 | 730 | 8~11 | Y200L-8 | 15 | 4904×3023×2943 |

| YAH1848 | 1 | 8.6 | 6-50 | ≤0-150 | 350-1000 | 730 | 8~11 | Y200L-8 | 15 | 4904×3023×2943 |

| 2YAH1848 | 2 | 8.6 | 30-150 | ≤400 | 350-1000 | 730 | 8~11 | Y200L-8 | 15 | 4904×3023×2943 |

| YA2148 | 1 | 10 | 30-150 | ≤210 | 180-630 | 730 | 8~11 | Y200L-8 | 15 | 4904×3023×2943 |

| 2YA2148 | 2 | 10 | 6-50 | ≤210 | 180-630 | 730 | 8~11 | Y225M-8 | 15 | 4904×3023×2943 |

| YAH2148 | 1 | 10 | 6-50 | ≤400 | 270-1200 | 730 | 8~11 | Y225M-8 | 15 | 4945×3423×3501 |

| 2YAH2148 | 2 | 10 | 13-200 | ≤400 | 270-1200 | 730 | 8~11 | Y225M-8 | 22 | 6092×3463×3674 |

| YA2160 | 1 | 12.6 | 30-150 | ≤200 | 230-800 | 730 | 8~11 | Y225M-8 | 22 | 6092×3463×3674 |

| 2YA2160 | 2 | 12.6 | 3-80 | ≤200 | 230-800 | 730 | 8~11 | Y225M-8 | 22 | 6116×3619×3849 |

| 3YA2160 | 3 | 12.6 | 6-50 | ≤200 | 350-1500 | 730 | 8~11 | Y250M-8 | 22 | 73553647×4420 |

| YAH2160 | 1 | 12.6 | 6-50 | ≤400 | 350-1500 | 730 | 8~11 | Y250M-8 | 22 | 6116×3619×3849 |

| 2YAH2160 | 2 | 12.6 | 30-150 | ≤400 | 200-700 | 730 | 8~11 | Y250M-8 | 30 | 6116×3619×3849 |

| YA2448 | 1 | 11.5 | 6-50 | ≤200 | 310-1300 | 730 | 8~11 | Y225M-8 | 30 | 4945×3729×3473 |

| YAH2448 | 1 | 11.5 | 6-50 | ≤400 | 310-1300 | 730 | 8~11 | Y250M-8 | 30 | 4969×3925×3638 |

| 2YAH2448 | 2 | 11.5 | 30-150 | ≤400 | 260-840 | 730 | 8~11 | Y250M-8 | 22 | 4969×3925×3638 |

| YA2460 | 1 | 14.4 | 30-150 | ≤200 | 260-840 | 730 | 8~11 | Y250M-8 | 30 | 6091×3925×3850 |

| 2YA2460 | 2 | 14.4 | 6-50 | ≤200 | 260-840 | 730 | 8~11 | Y250M-8 | 30 | 6091×3925×3850 |

| 3YA2460 | 3 | 14.4 | 6-50 | ≤200 | 400-1700 | 730 | 8~11 | Y250M-8 | 30 | 6088×3916×4478 |

| YAH2460 | 1 | 14.4 | 30-150 | ≤400 | 400-1700 | 730 | 8~11 | Y250M-8 | 30 | 6091×3825×3850 |

| 2YAH2460 | 2 | 14.4 | 30-150 | ≤400 | 400-1700 | 730 | 8~11 | Y250M-8 | 30 | 6091×3825×3850 |

Contact form description text