Multicylinder Hydraulic Cone Crusher

Multicylinder Hydraulic Cone Crusher

Multicylinder hydraulic cone crusher integrated crushing speed, stroke and crushing chamber ideally, not only improving the capacity and quality, but also expanding the range of applications, from limestone to iron ore, roadbed stone to manufactured sand and small mobile crushing station. HPS series cone crusher shows the excellent crushing capacity in secondary crushing and fine crushing from rock with high hardness to conventional rock.

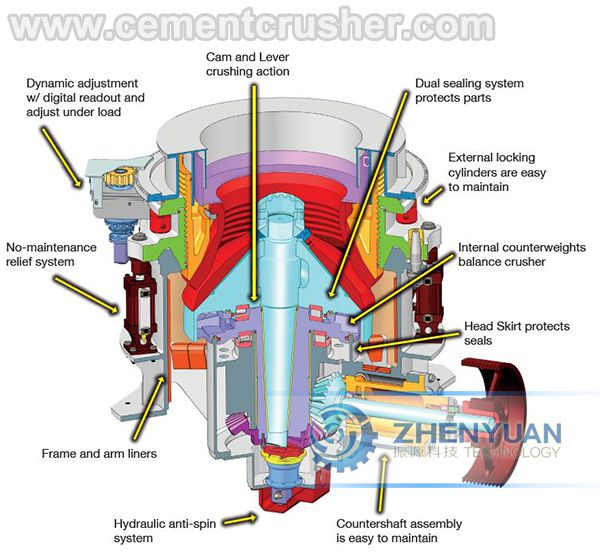

Multicylinder hydraulic cone crusher structure:

Application:

Multicylinder hydraulic cone crusher is applied to cement mill, mining, building construction, road &bridge construction, railway construction and metallurgy and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusher.

Advantages:

1. Upgraded structure and high efficiency.

2. Laminated crushing brings good product shape.

3. Optimized Lining Plate

4. Hydraulic motor for adjusting the discharge opening.

5. Hydraulic Insurance and Automatic Clearing

6. Multiple Seal Protection Device

7. Integrated Hydraulic Lubricating System

8. Unique Bearing Design

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

| Multicylinder Hydraulic Cone Crusher Techical Data | |||||||

| Model | Cavity Type | Standard Type | Short Type | Power (KW) |

Capacity (t/h) |

||

| Inlet Size (mm) | Min. Outlet Size (mm) | Inlet Size (mm) | Min. Outlet Size (mm) | ||||

| HPX 200 | Extra Coarse | 132-200 | 90-250 | ||||

| Coarse | 185 | 19 | 76 | 10 | |||

| Medium | 125 | 17 | 54 | 6 | |||

| Fine | 95 | 13 | 23 | 6 | |||

| Extra Fine | 10 | 5 | |||||

| HPX 300 | Extra Coarse | 230 | 25 | 180-250 | 115-440 | ||

| Coarse | 210 | 20 | 75 | 10 | |||

| Medium | 150 | 15 | 50 | 8 | |||

| Fine | 105 | 10 | 20 | 6 | |||

| Extra Fine | 20 | 6 | |||||

| HPX 400 | Extra Coarse | 295 | 30 | 280-355 | 140-630 | ||

| Coarse | 250 | 25 | 90 | 10 | |||

| Medium | 195 | 20 | 50 | 8 | |||

| Fine | 110 | 14 | 40 | 6 | |||

| Extra Fine | 30 | 6 | |||||

| HPX 500 | Extra Coarse | 330 | 30 | 355-450 | 175-790 | ||

| Coarse | 285 | 25 | 90 | 13 | |||

| Medium | 200 | 20 | 55 | 10 | |||

| Fine | 133 | 16 | 40 | 8 | |||

| Extra Fine | 35 | 6 | |||||

| HPX 800 | Extra Coarse | 353 | 32 | 550-630 | 260-1200 | ||

| Coarse | 297 | 32 | 155 | 13 | |||

| Medium | 267 | 25 | 92 | 10 | |||

| Fine | 219 | 16 | 33 | 6 | |||

| Extra Fine | |||||||