5X High Efficiency Centrifugal Impact Crusher

5X High Efficiency Centrifugal Impact Crusher

Our company developed the new 5X sand machine, integrating three kind of crushing mode; it is the core equipment in construction, mining metallurgical industry as well as highways, railways, bridges, water and electricity, mineral grinding field and machine-made sand industry at home and aboard. 5X series new sand making machine (centrifugal impact crusher) is widely used in various kinds of metal and non-metallic ores, cement, refractory matter, abrasives, glass raw materials, construction aggregate, machine-made sand, metallurgy and other industries. It is suitable for medium and fine crushing all kinds of ores and rocks with different hardness, such as iron ore, non-ferrous metal ore, corundum, bauxite, quartz sand, brown aluminum oxide, perlite, basalt and other high hardness materials.

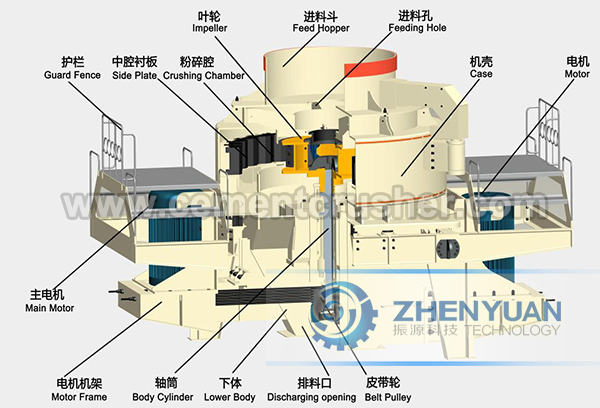

Structure:

Working Principle:

Material falls into feed hopper, and then it will be thrown by revolving rotor and hit a part of falling material, and these material will be taken to whirlpool material liner (ore impact block), and bounce to the top of crushing cavity, then move downward, impact with other material from impeller passage, finally discharged from the bottom.

Features:

- Combined type hammer design, only need to replace worn hammer, saving 30% cost. It also adds the deputy hammer, which effectively prevents the plate from damage after primary hammer worn.

- The core wear-resisting material is highly wear resistant and high temperature resistant material which used by the important industry of America.

- Using rhombic impact block to avoid the material damaging the plate after they ground.

- Bearings are imported from Japan, Sweden, the Untied States and other international brands.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

| 5X Vertical Shaft Impact Crusher | |||||

| Model | 5X7615 | 5X8522 | 5X9532 | 5X1145 | |

| Capacity(t/h) | Central Feeding and Circular Cascade Feeding | 150-280 | 240-380 | 350-540 | 500-640 |

| Fully Central Feeding | 70-140 | 120-200 | 180-280 | 250-360 | |

| Max.Feeding Size(mm) | Soft Material | 35 | 40 | 45 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | |

| Rotation Speed(RPM) | 1700-1900 | 1500-1700 | 1300-1510 | 1100-1310 | |

| Double-motor Power(KW) | 150 | 220 | 264 | 440 | |

| Dimension(mm) | 4100Х2330Х2300 | 4140Х2500Х2700 | 4560Х2600Х2900 | 5100Х2790Х3320 | |

| Weight(t) | 12.1 | 14.8 | 18.6 | 27.5 | |

| Thin Oil Lubrication Station | Double Oil Pump Motor Power(KW) | 2Х0.31 | |||

| Safety Protection | Double oil pumps assure enough oil supply. Automatic stop without oil flow and oil pressure; lowering temperature by water cooling; warm start for motor in winter. | ||||

| Dimension(mm) | 820Х520Х1270 | ||||

| Heater Power of Oil Tank(KW) | 2 | ||||