Belt Conveyor

Belt Conveyor

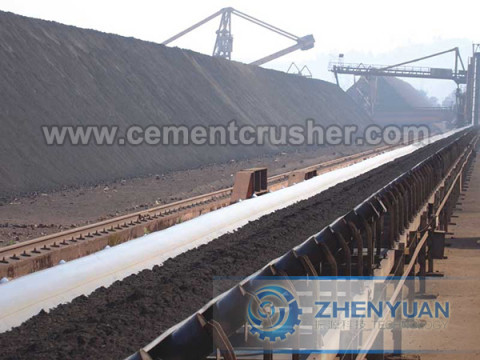

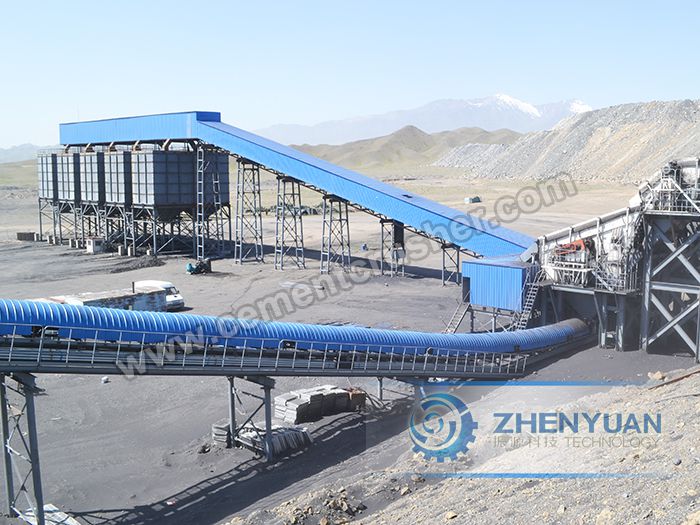

Zhenyuan belt conveyors and industrial belt conveyor systems for process plant facilities are supplied in a diverse range of innovative modular designs suitable for bulk handling applications.

Trough belt conveyor assemblies and the new range of Zhenyuan belt conveyors are ergonomically designed and constructed utilizing enhanced waste reduction features. These systems are capable of withstanding harsh terrain and bulk materials typically found within industries as outlined:

iron ore & gold

coal & fly ash

aggregates

sand & gravel

pulp & paper

agricultural

chemical

food processing

Process plant & allied industries.

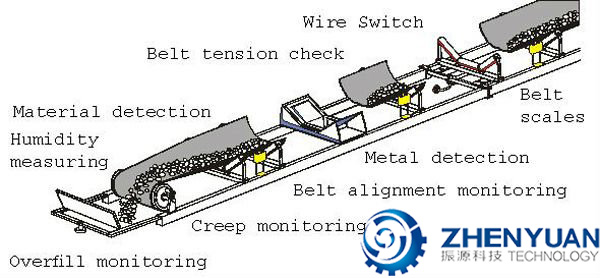

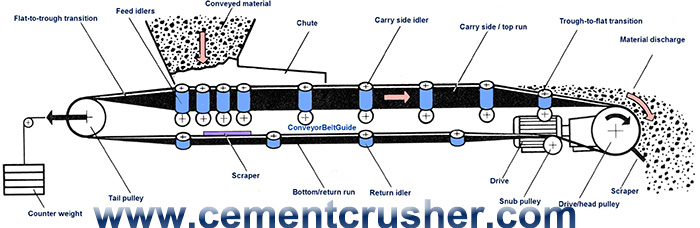

Structure:

Performance Features:

450mm to 1400mm belt widths

Modular sturdy-channel section design

20, 35 or 45 degree trough angle frames

Spillage reduction features & skirts

Conveyor-belt-cleaner / Primary cleaner

Drive roller rubber lagged, crowned end pulleys

Belt speed optioned to suit load capacity

Medium or Heavy duty belt-idler-pulleys, bearings and components

Optional Features:

Feed hopper & additional rubber skirting

Belt training, impact and energy efficient composite idlers

Access gantry, canopies & dust proofing.

Customized widths, supports, stands and stringers

Conveyor-belt-installations & re-furbishments

Fertilizer-conveyors, stainless constructions or Galvanized coatings

The advantages of our belt conveyor:high capacity,simple structure,easy maintenance,standard spare parts.According to the different demands,the transfer system can be aslpe or installed horizontally to meet the needs of different plant.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

| Belt width (mm) | Belt Length(m) / Power(KW) | Belt Speed (m/s) | Capacity (t/h) | ||

| 400 | ≤12 / 1.5 | 12-20 / 2.2 | 20-25 / 3 | 0.8-2 | 40-80 |

| 500 | ≤12 / 3 | 12-20 / 4 | 20-30 / 5.5 | 0.8-2 | 78-191 |

| 650 | ≤12 / 4 | 12-20 / 5.5 | 20-30 / 7.5 | 0.8-2 | 131-323 |

| 800 | ≤10 / 4 | 10-15 / 5.5 | 15-25 / 7.5 | 1.0-2 | 278-546 |

| 1000 | ≤10 / 5.5 | 10-20 / 7.5 | 20-25 / 11 | 1.0-2 | 435-853 |

| 1200 | ≤10 / 7.5 | 12-20 / 11 | 20-25 / 15 | 1.0-2 | 655-1284 |