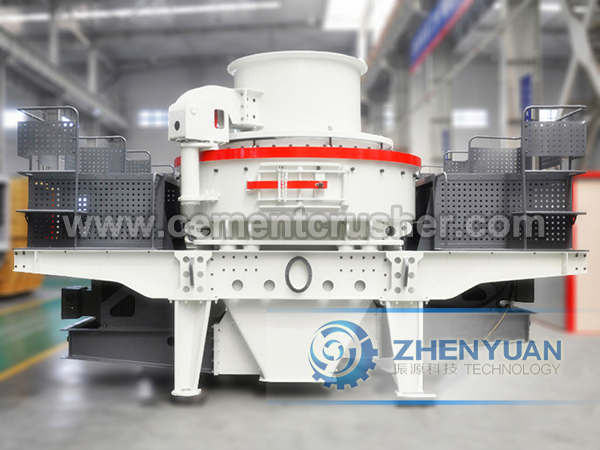

VSI High Efficiency Vertical Shaft Impact Crusher

VSI High Efficiency Vertical Shaft Impact Crusher

Vertical shaft impact crusher also know as sand making machine is applied widely for the powder process of mineral product including mental and non-metal ore, fireproof material, bauxite, diamond dust, glass raw materials, architectural materials, artificial sand and all kinds of metal ore materials, especially which has more advantages than any other machines in processing the more and most hard materials.

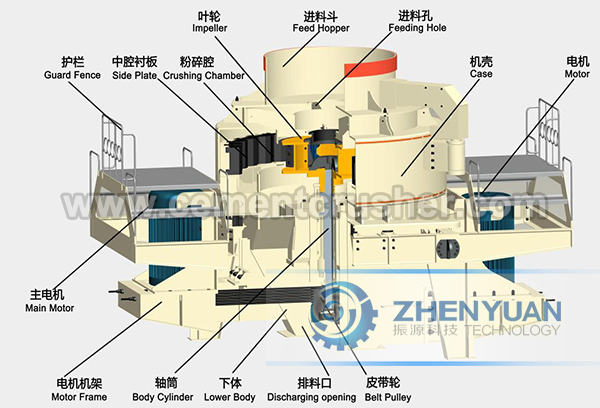

Structure:

Application:

1.River stone, mountain stone(limestone, basalt, granite, diabase, andesite. etc), Ore tailings, aggregate chips

2.Hydraulic and hydroelectric engineering, high-level road, highway and railway, passenger rail line, bridge, airport runway, municipal projects, sand making and rock reshaping

- Building aggregate, highway road fabrics, cushion material, asphalt concrete and cement concrete aggregate.

- Crushing progress before grinding in mining field. The crushing of building material, metallurgy, chemical industry, mining, fireproofing, cement, abrasive, etc.

5.Breaking of high abrasive and secondary disintegration, sulfur in thermal power and metallurgy industry, environmental projects such as slag, construction waste crushing

6.Manufacturing of glass, quartz sand and other high purity material

Features:

- Produces a product of superior cubical shape

- Ability to control product grading by cascading and tip speed

- Low wear costs due to unique rock-on-rock crushing

- Accepts fine material in feed

- Gradation control

- Simple maintenance

- High product yield

- Non-plugging crushing chamber

- Variable reduction ratios

- Heavy duty design

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

| VSI Sand Making Machine | |||||

| Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | |

| Capacity(t/h) | Central Feeding and Circular Cascade Feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Fully Central Feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Max.Feeding Size(mm) | Soft Material | <35 | <40 | <45 | <50 |

| Hard Material | <30 | <35 | <40 | <45 | |

| Rotation Speed(RPM) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Motor Model | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | |

| Double-motor Power(KW) | 2*55 | 2*90 | 2*132 | 2*200 | |

| Dimension(mm) | 3600*2248*2533 | 4378*2350*2667 | 4640*2650*2800 | 5570*2900*3000 | |

| Weight(t) | 10 | 12 | 16 | 25.6 | |

| Thin Oil Lubrication Station | Flow Rate(L/min) | 6 | |||

| Double Oil Pump Motor Power(KW) | 2Х0.31 | ||||

| Safety Protection | Double oil pumps assure enough oil supply. Automatic stop without oil flow and oil pressure; lowering temperature by water cooling; warm start for motor in winter. | ||||

| Dimension(mm) | 820Х520Х1270 | ||||

| Heater Power of Oil Tank(KW) | 2 | ||||